Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

Have you ever wondered how electrical devices like motors and transformers function efficiently? The answer lies in the magnet wire inside. Magnet wire is coated with enamel for insulation, but removing this coating is essential for creating proper electrical connections.

In this post, we’ll explore why enamel removal is crucial and provide practical methods to strip it safely and effectively. You'll learn how to choose the right technique for your project and avoid common mistakes.

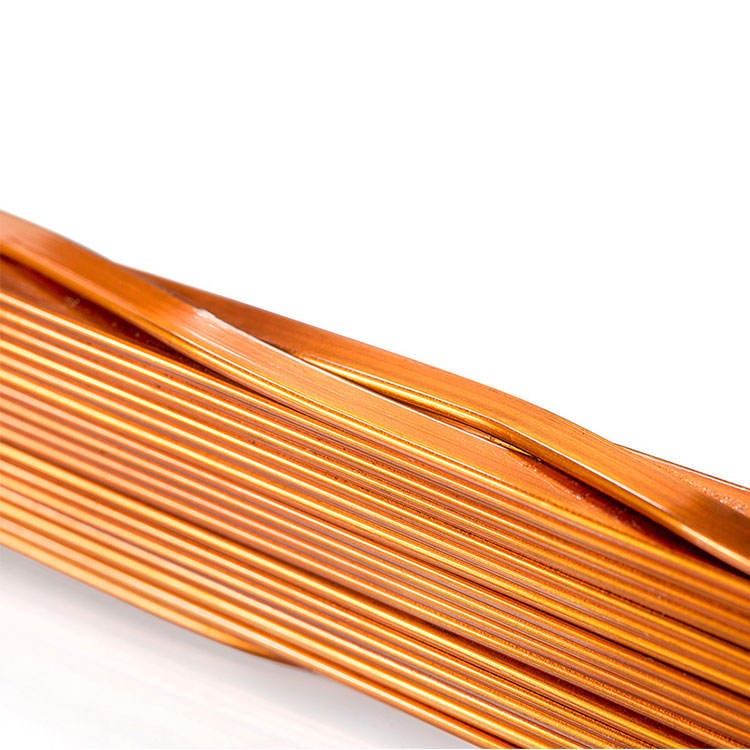

Magnet wire, also known as enameled wire, is a type of copper or aluminum wire coated with an insulating layer of enamel. It is commonly used in applications like transformers, motors, and inductors. This wire is designed for winding into coils, which are essential in generating magnetic fields. Its ability to conduct electricity while being insulated makes it ideal for electromagnetic uses in various devices.

The enamel coating serves as an electrical insulator, preventing short circuits when the wire is wound into coils. Without this insulation, the conductive metal in the wire could come into contact with other conductive materials, causing inefficiencies or damage. Additionally, the enamel helps protect the wire from environmental factors like moisture and mechanical wear, ensuring long-lasting performance in electrical systems.

Stripping enamel from magnet wire is essential for creating effective electrical connections. During soldering, the enamel coating must be removed to expose the conductive copper or aluminum underneath. Without this step, the solder won’t adhere properly, leading to weak or unreliable connections. Proper wire stripping ensures the wire is ready for secure and efficient electrical termination, which is crucial for the performance and safety of electrical devices.

Improper enamel removal can lead to several issues. If the enamel isn’t fully stripped, it can prevent the solder from bonding properly, causing poor electrical connections. This can result in malfunctioning or inefficient devices. Additionally, excessive force or incorrect methods can damage the wire, weakening its structure and affecting its ability to conduct electricity. Ensuring that the enamel is removed correctly is critical to avoid these risks and ensure optimal functionality.

Removing enamel from magnet wire is essential for preparing the wire for use in electrical connections. Various methods are available, each suitable for different applications and wire types. Here, we explore six effective techniques for enamel removal, from manual scraping to advanced laser stripping.

Manual scraping is one of the most basic methods of removing enamel from magnet wire. This technique involves using a sharp tool, like a utility knife or sandpaper, to physically scrape off the enamel coating. The process requires patience and precision, making it suitable for small-scale projects or when dealing with fine, delicate wires.

To begin, gently score the enamel coating using a utility knife or scrape it off using sandpaper. It’s important to apply light pressure to avoid damaging the underlying wire. By rotating the wire as you scrape, you ensure that the enamel is evenly removed. Manual scraping allows for precise control, but it can be slow and labor-intensive.

This method is best applied for small quantities of wire or when precision is required, such as in intricate soldering tasks or fine electronic work. It is ideal for DIY projects or repairing small electronics where a high level of accuracy is necessary. For larger, industrial-scale projects, other methods may be more efficient.

| Pros | Cons |

|---|---|

| Low cost and readily available tools | Time-consuming, especially for large projects |

| Precise and controlled removal | Risk of damaging the wire if not done carefully |

| No need for special equipment | Requires steady hands and attention to detail |

Chemical stripping is an effective way to dissolve the enamel coating without physically scraping it off. This method involves applying commercial enamel removers or solvents to the wire, which break down the coating and make it easy to wipe away.

Chemical enamel removers are typically applied by soaking the magnet wire in the solvent or brushing it onto the enamel coating. Once the enamel begins to soften or dissolve, you can wipe or scrape it away. The advantage of this method is that it’s less labor-intensive compared to manual scraping and can handle larger quantities of wire more quickly.

Ventilation: Always work in a well-ventilated area. The fumes from some enamel removers can be toxic or irritating to the respiratory system.

Protective Gear: Wear gloves and safety goggles to protect your skin and eyes from chemicals. Some solvents can cause skin irritation or burns.

Proper Disposal: Ensure that you dispose of any leftover chemicals or contaminated materials in accordance with local regulations to minimize environmental impact.

Chemical stripping is ideal for medium to large-scale wire stripping tasks, especially when you need to quickly process a batch of magnet wire. It's often used in industrial settings or when dealing with thicker enamel coatings that might be difficult to remove by hand.

| Pros | Cons |

|---|---|

| Faster than manual methods | Requires chemical handling, which poses safety risks |

| Effective for larger wire quantities | Can damage the wire if not used properly |

| Minimal physical effort required | Requires good ventilation and proper disposal |

Thermal stripping uses heat to soften and burn off the enamel coating. By applying heat through a soldering iron or heat gun, you can quickly strip the enamel without physical contact. The heat softens the enamel, allowing it to be easily wiped or scraped away.

Start by heating the wire with a soldering iron or heat gun. The heat causes the enamel to melt, allowing you to remove it without damaging the wire underneath. Be careful not to overheat the wire, as excessive heat can weaken the wire or damage its insulation. After applying heat, you can use a soft cloth or scraper to wipe away the enamel.

Control the Temperature: Use a heat gun or soldering iron with adjustable temperature settings. Keep the heat at a moderate level to prevent damage to the wire.

Test on a Sample: Before applying heat to your entire batch of wire, test on a small section to ensure the enamel melts without harming the wire.

Thermal stripping is effective for both small and medium projects. It's particularly useful when you need to strip enamel quickly and when other methods, like manual scraping, are too slow. It’s often used in electronics or DIY projects where time is a factor.

| Pros | Cons |

|---|---|

| Fast and efficient for many types of wire | Overheating can cause wire damage |

| Minimal physical labor | Not ideal for delicate wires or fine work |

| Works well on thick enamel coatings | Requires careful monitoring of temperature |

Grinding and abrasive stripping involves using abrasive materials like emery cloth, sandpaper, or a grinding tool to physically wear away the enamel coating. This method is ideal for larger, more robust wires that can handle abrasive treatment.

The wire is either rubbed against sandpaper or placed in contact with a rotating grinding wheel. The abrasive material removes the enamel by scraping or grinding it off the wire. This method is highly effective for wires with thick or stubborn enamel coatings.

| Pros | Cons |

|---|---|

| Works well for tough, thick enamel coatings | Can cause wear or damage to the wire if done improperly |

| Suitable for larger quantities of wire | Messy and may create debris |

| Can be used on wires that are resistant to other methods | Not ideal for delicate or fine wires |

Grinding and abrasive stripping is best used for industrial or large-scale projects where the wire is thick and strong. It’s also useful when removing enamel from copper wires in bulk, such as in manufacturing or electrical component recycling.

Ultrasonic stripping is a highly specialized and advanced method that uses ultrasonic waves to break down and remove the enamel coating from the wire. This process is highly precise and ideal for delicate or complex wire stripping tasks.

Ultrasonic stripping involves immersing the magnet wire in a bath of liquid that vibrates at ultrasonic frequencies. These vibrations break up the enamel coating without damaging the wire. This method is precise and works well for fine wires that need to be stripped without any physical contact.

Ultrasonic stripping is used primarily in high-tech or sensitive industries where precision is crucial. It’s ideal for delicate wires used in small electronics, medical devices, or other high-precision equipment where even the slightest damage can affect functionality.

| Pros | Cons |

|---|---|

| Highly precise and gentle | Requires specialized equipment |

| Does not damage the wire | Expensive and less accessible for DIY projects |

| Ideal for fine or delicate wires | Not practical for large, thick wires |

Laser stripping is an advanced technique that uses lasers to precisely remove the enamel from magnet wire. The laser is focused on the enamel coating, which is vaporized or burned off without affecting the wire underneath.

A laser beam is directed at the enamel coating on the wire. The intense heat from the laser causes the enamel to evaporate, leaving the underlying wire intact. This method is highly precise and offers the ability to strip enamel from very small or fine wires without risk of damage.

Laser stripping is typically used in high-tech industries where precision is essential, such as in aerospace, medical devices, or advanced electronics. It’s ideal for wires with very thin enamel coatings or for high-precision applications.

| Pros | Cons |

|---|---|

| Extremely precise and accurate | Expensive and requires specialized equipment |

| No contact with the wire, preventing physical damage | Not widely available for DIY or small-scale use |

| Suitable for small, delicate wires | Requires trained professionals to operate the equipment |

When choosing the right method for removing enamel from magnet wire, consider the scale of your project, the type of wire you're working with, and the level of precision required. Different methods are better suited for specific tasks, and selecting the wrong one can lead to inefficiencies or damage to the wire.

Project Scale: For small-scale or DIY projects, hand tools like utility knives or sandpaper may suffice. For larger projects, consider methods like chemical stripping or thermal stripping for faster results.

Wire Type: The thickness of the enamel and wire material (copper vs. aluminum) can determine the best method. Thicker wires or tougher coatings might need more robust methods like grinding or chemical solvents.

Precision Requirements: If your project demands high precision, like in fine electronics, ultrasonic or laser stripping methods might be necessary, as they offer precise control and minimal damage.

Choosing the right method ensures that you complete your task efficiently and with minimal risk of damaging the wire.

Effective enamel removal is crucial to ensure proper electrical connections without damaging the wire. Below are some best practices that can help improve the efficiency of your wire stripping process.

Work in a Well-Lit Area: This allows you to see exactly where the enamel is being removed, reducing the risk of damaging the wire.

Use the Right Tools for the Job: Always use tools that are suitable for the wire type and enamel thickness. For delicate tasks, avoid aggressive methods that could damage the wire.

Test First: Always try your chosen method on a small section of the wire to ensure it works effectively without harming the wire. This is especially important when using chemical solvents or heat.

Clean the Wire After Removal: After stripping the enamel, clean the wire to remove any residual chemicals or debris that may affect the connection.

Be Gentle: Whether you're scraping, grinding, or applying heat, always handle the wire carefully to avoid overworking or damaging it.

To remove enamel from magnet wire effectively, consider the project scale, wire type, and precision needed. Methods like manual scraping, chemical stripping, and thermal stripping work best based on these factors. Always use the right tools and follow safety precautions to avoid damaging the wire. Practice on sample wire and clean thoroughly after removal for optimal results.

By following these best practices, you can achieve safe and efficient enamel removal for your projects.

A: Magnet wire, or enameled wire, is commonly used in applications like transformers, motors, and inductors. Its enamel coating provides insulation, preventing short circuits when the wire is wound into coils.

A: Enamel can be removed using various methods such as manual scraping, chemical stripping, thermal stripping, grinding, ultrasonic stripping, or laser stripping. The choice depends on the project scale and precision required.

A: Chemical stripping and thermal stripping are effective when done carefully. Always wear safety equipment and work in a well-ventilated area to minimize risks.