Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Have you ever wondered how electrical devices maintain performance while minimizing space? Enameled copper wire plays a critical role in this. It's essential for electrical systems, offering excellent conductivity and insulation.

In this post, we’ll discuss the key steps in the manufacturing process of enameled copper wire, which directly affects its quality and efficiency in applications such as motors and transformers. You'll learn about the materials, techniques, and tests involved in creating high-quality wire.

Enameled copper wire is a type of wire used widely in electrical applications. It's made from a copper conductor coated with a layer of enamel insulation. This design allows the wire to conduct electricity while preventing short circuits or damage caused by external factors.

Copper conductor: Known for its excellent electrical conductivity, copper is the core material. It's ideal for transmitting power efficiently.

Enamel insulation: This thin coating of enamel (polyester, polyurethane, or polyamide-imide) surrounds the copper wire, providing electrical insulation. It helps in protecting the wire from environmental factors, including moisture and heat.

Enameled copper wire is used in many electrical components. It plays a crucial role in:

Transformers: Helps in transmitting electrical energy.

Motors: Used for winding in electric motors, where it’s essential for creating magnetic fields.

Other electrical components: Found in devices like speakers, relays, and inductors.

The production of enameled copper wire is a complex process that requires precision at every step to ensure the final product meets the necessary standards for electrical components. The manufacturing of this wire involves several critical stages, each contributing to the wire’s performance, durability, and reliability. Let’s walk through the key steps involved in making enameled copper wire.

The journey begins with the careful selection of the materials. In this step, two main components are chosen: the copper conductor and the enamel insulation.

Copper wire as the base material: The heart of the wire is copper, a material chosen for its high electrical conductivity. Copper offers one of the best conductivities among all metals, making it ideal for carrying electrical currents. The higher the purity of the copper, the better the wire will perform. For high-quality enameled copper wire, manufacturers use copper with purity levels of 99.99%. This ensures minimal resistance and maximum efficiency in the transmission of electricity.

Enamel insulation materials: The next critical part of the wire is the insulation. The insulation prevents the wire from short-circuiting and ensures the safe and efficient operation of the wire within electrical components. There are several types of enamel used, including:

Polyurethane: Offers excellent mechanical properties and is commonly used for motor winding applications.

Polyester: Provides good thermal stability and is often used for wires operating in moderate temperature ranges.

Polyamide-imide: Known for its high heat resistance, it’s used for wires that need to operate in extreme conditions.

Each type of enamel provides different thermal and electrical properties, which are selected based on the wire's intended application.

Once the materials are ready, the next step is the transformation of raw copper into a wire that can be used in electrical devices. This involves two important processes: wire drawing and annealing.

Wire drawing: The process begins by taking copper rods and pulling them through a series of dies to reduce their diameter. This process is called wire drawing. Each time the copper is drawn through a die, it becomes thinner and longer. The goal is to produce wires of the desired diameter, typically ranging from a few millimeters to micrometers. Wire drawing also improves the mechanical properties of the copper, such as tensile strength, making the wire strong enough for use in various applications.

Annealing: After the copper wire is drawn, it often undergoes a process known as annealing. This is essentially a heat treatment that softens the wire. During this stage, the copper wire is heated to a specific temperature and then slowly cooled. Annealing helps restore the copper's flexibility, which is crucial for the next steps in the process. It also reduces oxidation and improves the wire's workability. Without annealing, the copper would be too brittle to withstand the next phases of coating and winding.

Once the wire is prepared, it is coated with insulating enamel to prevent electrical shorts and enhance its performance in different applications.

Extrusion and dipping methods: There are two primary methods for applying enamel to the copper wire:

Extrusion: In this method, the copper wire is passed through a die that applies a uniform layer of enamel to the wire’s surface. The enamel is extruded directly onto the copper, ensuring that the coating is evenly distributed.

Dipping: In the dipping method, the wire is immersed in a bath of melted enamel. The wire is pulled through the bath and then cooled, allowing the enamel to solidify and form a protective coating. Dipping is typically used for larger wires and offers a thicker coat of enamel.

Multiple layers of enamel: To ensure the wire is well-insulated, manufacturers often apply several layers of enamel. Each layer adds to the wire’s insulation, creating a barrier that protects the copper from environmental factors like heat, moisture, and mechanical wear.

Uniform enamel coating: The uniformity of the enamel coating is crucial to the performance of the wire. If the enamel layer is too thin or uneven, it can lead to weak insulation, which may cause short circuits or failure of the wire in electrical applications. Therefore, maintaining consistent coating thickness is essential for the wire's durability and efficiency.

After the enamel is applied, the next step is curing and drying. This stage solidifies the enamel and ensures it adheres firmly to the copper wire.

Curing process: The coated wire is passed through an oven or heated chamber where it is exposed to high temperatures. The purpose of curing is to harden the enamel and remove any remaining solvents. This process is vital because it enhances the adhesion of the enamel to the copper conductor. Curing also strengthens the enamel's mechanical properties and increases its ability to withstand harsh environmental conditions like heat and humidity.

Controlled temperature: It’s essential to control the temperature during the curing process. If the temperature is too low, the enamel may not cure properly, leaving behind solvent residues that weaken the coating. On the other hand, if the temperature is too high, the enamel may become brittle, which could lead to cracks in the coating. Achieving the correct curing temperature ensures the enamel is durable and performs well over time.

Once the enamel has been cured, the wire undergoes the final steps of cooling and surface finishing.

Cooling process: After the wire exits the curing oven, it’s still hot. It’s then cooled to room temperature to set the enamel and prevent any further changes in the coating. This cooling phase helps ensure the enamel hardens completely, making the wire ready for use in electrical components.

Surface finishing: Depending on the application, the wire may go through sanding or polishing. This optional step smooths the wire’s surface, making it easier to wind and ensuring a clean, uniform finish. It also reduces any sharp edges or imperfections that could interfere with the winding process or lead to damage during installation.

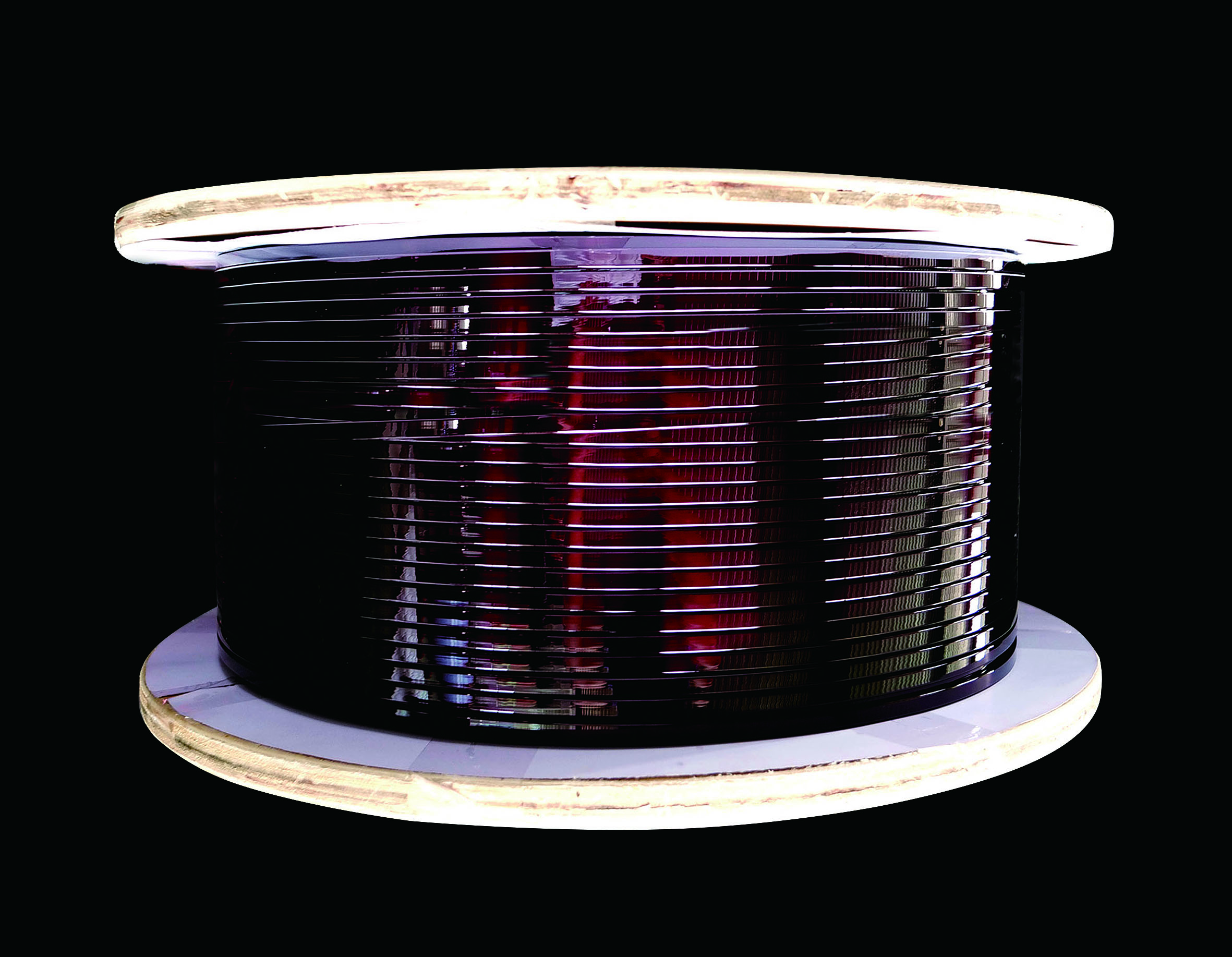

The wire is now ready for the final stages of manufacturing, where it can be wound, packaged, and distributed for use in various electrical devices.

When it comes to enameled copper wire, the choice of enamel coating is crucial for ensuring its performance in specific applications. There are several types of coatings, each offering unique properties to suit different needs. Let’s take a closer look at the most common types of enameled copper wire coatings.

| Coating Type | Temperature Resistance | Mechanical Strength | Insulation Properties | Common Uses |

|---|---|---|---|---|

| Polyester | Moderate (up to 130°C) | Good | Decent insulation for general applications | Household appliances, low to medium-temperature motors. |

| Polyurethane | Higher (up to 155°C) | Very good | Excellent insulation, protection from heat and moisture | High-efficiency motors, transformers, electronics. |

| Polyamide-Imide | High (up to 200°C or more) | Extremely high | Superior insulation, even in harsh environments | High-performance electrical devices, high-temperature motors, military-grade equipment. |

| Polyesterimide | High, similar to polyamide-imide | Very high | Excellent insulation, especially in high temperatures | Automotive, aerospace, motors, relays, transformers. |

Selecting the right enameled copper wire depends on the requirements of your application. Here’s a quick guide to help you decide:

High-Temperature Motors:

If you're dealing with motors that operate in extreme temperatures, you'll need a coating like polyamide-imide or polyesterimide. These coatings can handle temperatures up to 200°C, making them ideal for high-temperature environments.

High-Efficiency Transformers:

For transformers, which are expected to handle a lot of electrical load and heat, polyurethane or polyesterimide is the best choice. These coatings provide excellent insulation and can withstand the heat generated during operation.

General Motors and Appliances:

If your application involves everyday electronics or motors that don’t reach high temperatures, polyester is a good option. It offers decent insulation at a lower cost.

When producing enameled copper wire, maintaining high quality and consistency is crucial. The production process includes several critical tests to ensure the wire's performance meets industry standards. Let's dive into the key testing and quality control measures used in enameled copper wire production.

Two of the most important tests to ensure the wire’s insulation integrity are spark tests and dielectric testing.

Spark tests: These are used to check for any defects or breakdowns in the enamel coating. The wire is passed through an electric field, and if there's any crack or gap in the enamel, it will cause a spark. A successful spark test ensures that the wire is fully insulated and safe for use in electrical applications.

Dielectric testing: This test measures the insulation strength of the wire by applying high voltage and checking if the wire can withstand it without breaking down. It helps verify that the wire will perform safely and reliably under normal operating conditions.

Consistency in the wire’s diameter and tension is vital for ensuring its performance.

Diameter control: The wire’s diameter must remain uniform throughout the production process. Variations in diameter can affect the wire’s performance and the efficiency of the electrical system. Manufacturers use laser diameter sensors to monitor and maintain consistent diameter as the wire moves through different production stages.

Tension monitoring: During the enamel coating and winding processes, maintaining the right tension is essential. Too much tension can lead to breaks, while too little can result in uneven coating. Tension is continuously monitored to ensure the wire is wound tightly and uniformly, which also helps prevent defects and ensures smooth operation during future use.

Quality assurance (QA) is vital in enameled copper wire production. Without strict QA processes, there’s a higher risk of defects, which could lead to failures in the wire when used in high-demand applications.

Meeting industry standards: QA ensures the wire meets international and industry standards for insulation, diameter, and mechanical properties. This is essential for maintaining reliability, especially in applications like transformers, motors, and electronics.

Ensuring reliability: In high-stakes applications, such as aerospace or medical devices, any failure can have serious consequences. Rigorous QA testing ensures the wire can perform safely and efficiently for years, even in demanding environments.

The QA process involves continuous inspection, testing, and documentation at every step to verify that the wire meets all required specifications. Without effective QA, manufacturers cannot guarantee the wire’s long-term performance, potentially leading to product failure and financial loss.

The manufacturing process of enameled copper wire involves several key steps: material selection, wire drawing, enamel coating, curing, and surface finishing. Quality control ensures that the wire maintains its insulation integrity, consistent diameter, and optimal tension, making it reliable for various applications. Looking ahead, advancements in enamel coatings will further enhance wire performance, offering improved insulation and durability for future electrical systems. For more information or inquiries, please contact us.

A: The production involves selecting high-purity copper, drawing it into fine wire, applying enamel coatings for insulation, curing the enamel, and then cooling and finishing the wire for uniformity.

A: Common coatings include polyester, polyurethane, and polyamide-imide. Each offers different levels of temperature resistance, mechanical strength, and insulation properties, suited for various applications like motors and transformers.

A: Quality control ensures the wire meets industry standards for insulation, diameter, and mechanical properties. It helps guarantee performance and safety, especially in high-stakes applications.